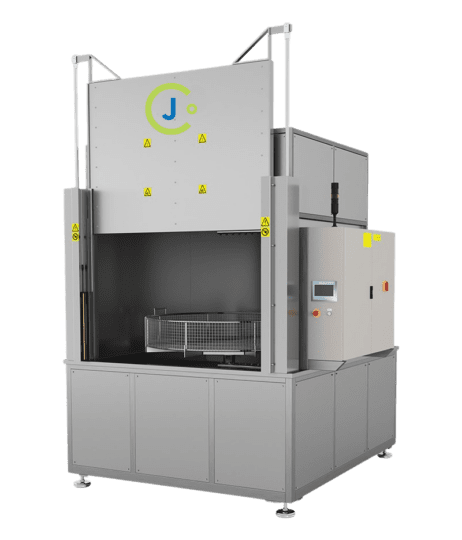

Spray Wash Cabinets for Cleaning Critical Parts

Critical parts require high levels of cleanliness that can be difficult to achieve. Jayco's team of process engineers have a deep understanding of aerospace and precision parts industries, taking the guesswork out.

We sit down with you to understand everything from cleanliness specifications, throughput needs, pre and post wash operations, available floor space, and regulatory. Nothing is overlooked.

Engineering the right production process, spray wash cabinet with fixtures, and chemistry to fit your demanding requirement.

Why Jayco Spray Wash Cabinets

Are Known as One of

The Best

-

Pressurized Adjustable Wand

Angled spray nozzle system for precise cleaning + variable speed rotating table.

-

Separate Clean and Rinse Tanks

Single or multiple tanks available for clean and rinse with separate heating.

-

Siemens Touchscreen

Program process recipes via touchscreen on multiple cleaning stage models.

-

Stainless Steel Construction

Entirely constructed from 304 stainless steel for years of rust free operation.

-

Parts Drying

Rotating hot air options for optimal drying of complex part features.

-

Large Part Capacity

Standard capacities up to 1,800 mm dia / 800 kg parts. Custom models available.

-

Industrial Automation

Manual or auto loader system for easy operation. Automatic chemical dosing.

-

Reliable Compact Design

Space-saving design. Responsive service and USA stocked parts to keep you running.

Frequently Asked Questions

A 2 years parts / 1 year labor is typical on most systems. Contact us for more details.