Precision Parts Cleaning Process

Jayco has been delivering critical cleaning systems for over 15 years to some of the leading precision parts manufacturers in North America.

- Pre and In Process Cleaning

- Passivation

- Final Cleaning

- Vacuum Assisted Cleaning & Drying

- Small Footprint

Precision Part Applications

Jayco has experience with providing proven cleaning solutions that meet the critical cleanliness you require.

- Additive manufactured

- Swiss machined, fasteners

- Hydraulic components

- Small ID tubing

- PVD and other vacuum coating

- Vacuum brazing

Manufacturing Soils

We've cleaned practically all traditional and emerging manufacturing process soils used to produce precision parts.

- Soils

- Coolant, oils, EDM fluid

- Particulate

- Swarf

- Fingerprints

- Grinding, lapping, polishing

Featured Customer

Micron Manufacturing (Precision Parts)

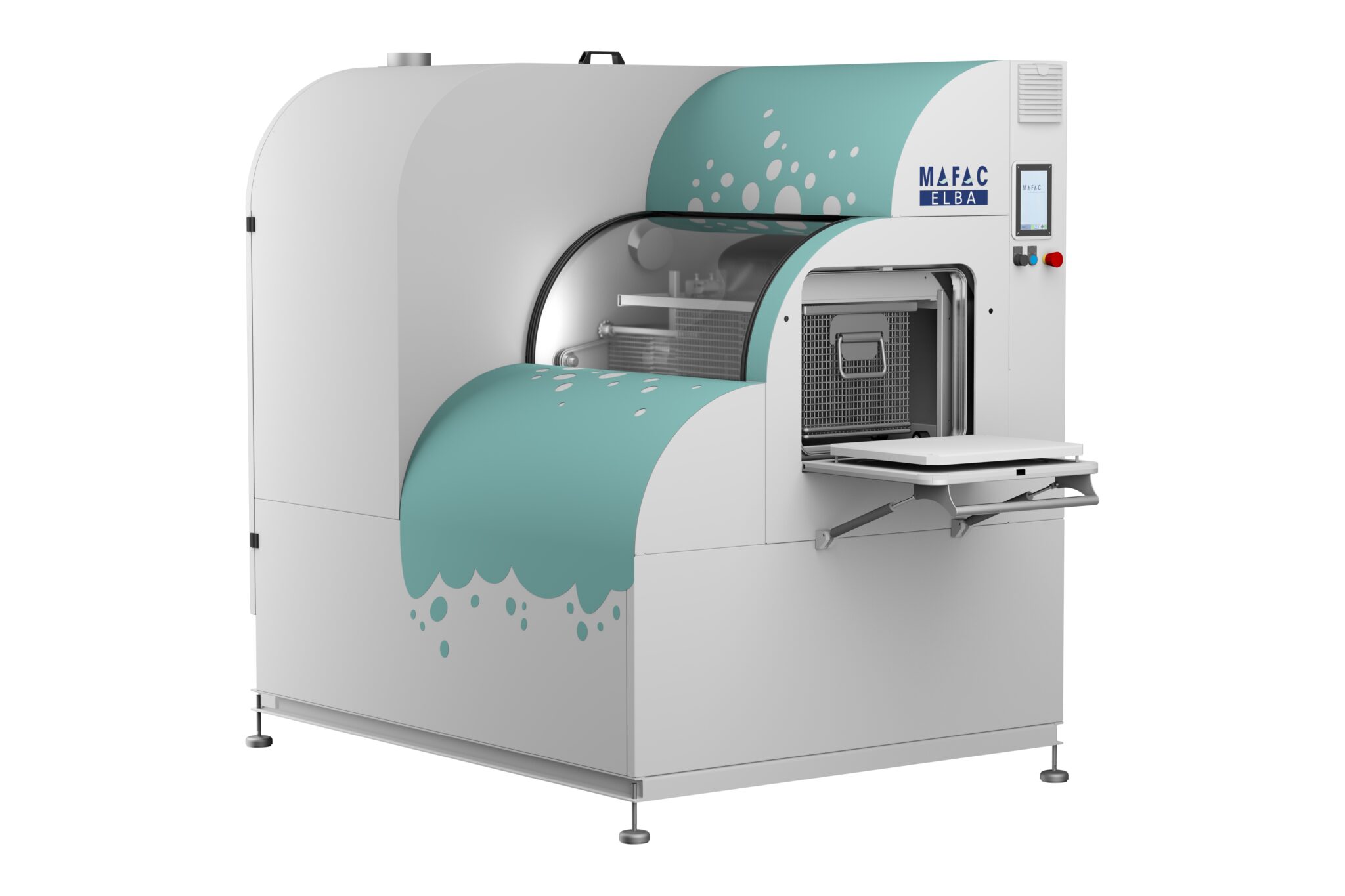

Micron chose Jayco to invest in a space-saving MAFAC Java rotary basket parts washer with conveyer.

We've run various test parts through the new system. These early results are fantastic, and indicate the system will deliver both a higher cleanliness standard and great time savings. Visually, the cleaned parts come out bright and shining, dry and free of chips.

Space-saving design for aqueous cleaning which includes our patented cleaning and drying under vacuum.

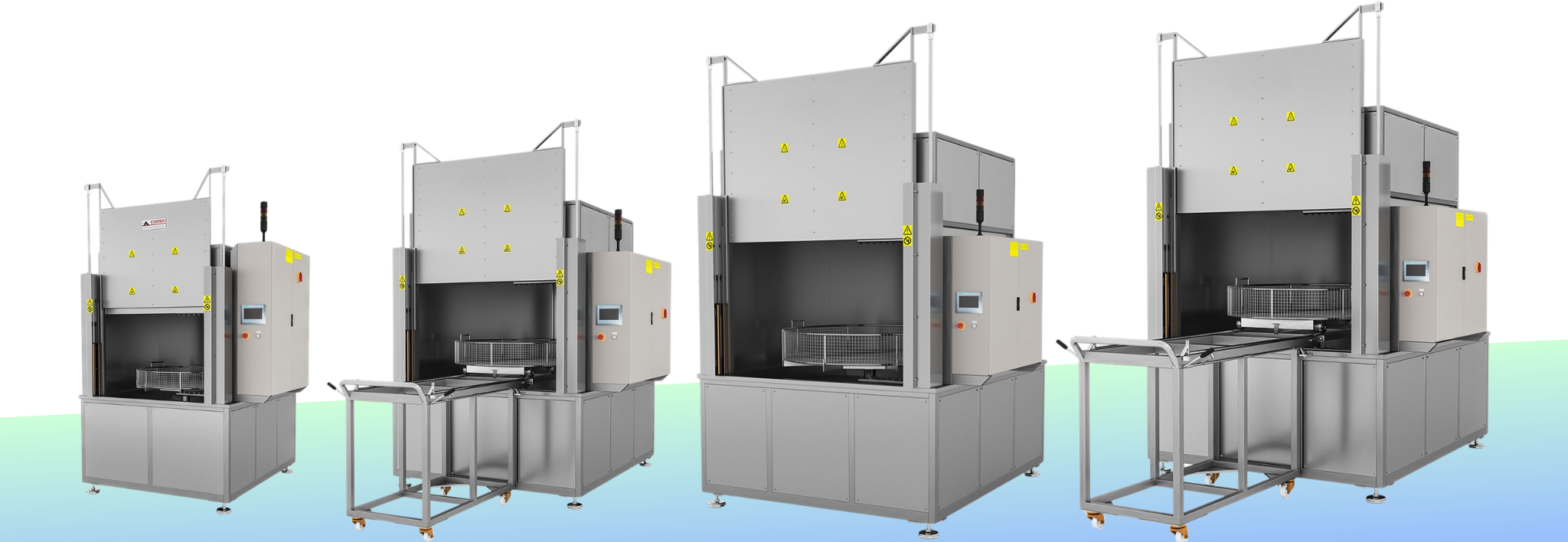

Modular immersion cleaning tanks with ultrasonics, rotation, drying, passivation, and automation.

Large parts capacity cabinet spray washers with separate wash / rinse tanks and hot air dry.

Frequently Asked Questions

Yes, the Jayco rotary basket washer with vacuum assist will thoroughly remove the EDM oil and remove the powder from internal metal printed part chambers.