Aerospace Parts Cleaning Process

Jayco has been delivering certified cleaning systems for over 15 years to some of the leading OEM and Tier 1 aerospace parts manufacturers in North America.

- Final Cleaning

- MRO Processing

- FPI Pre and Post Clean

- Laser Sintered Parts

Critical Cleaning

of Aerospace Parts

Jayco has experience with providing proven cleaning solutions that meet strict OEM aerospace cleanliness requirements.

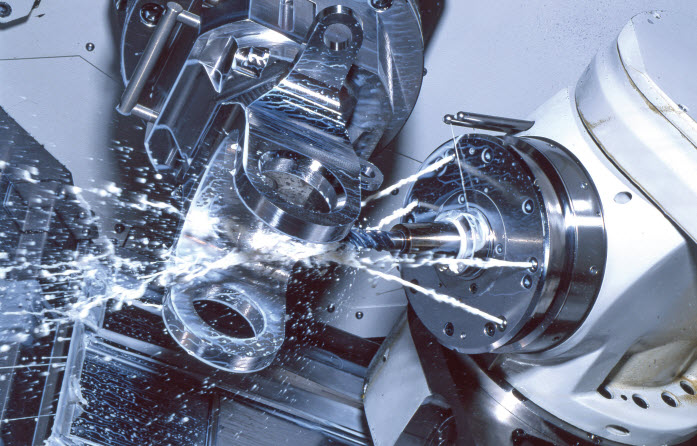

- Complex turbine blades

- Critical engine components

- Fasteners and tubing

- Hydraulics and actuation systems

- Additive manufactured

- Landing gear components

Manufacturing Soils

We've cleaned practically all traditional and emerging manufacturing process soils used to produce critical aerospace components.

- Fluorinated greases

- Machining oils

- FPI solution

- Particulates

- Skydrol

- Cosmoline

Featured Customer

Collins Aerospace (Additive Manufacturing)

Collins Aerospace chose Jayco to invest in a JCS ultrasonic tank line with vacuum drying for their laser sintered titanium parts.

After de-powdering, the part goes into a Jayco cleaning machine, which uses a cleaning agent and water to clean the part. Next is final shaping using an electrical discharge machining tool to remove excess metal, followed by heat treating.

Collins Aerospace chose Jayco to invest in a JCS ultrasonic tank line with vacuum drying for their laser sintered titanium parts.

After de-powdering, the part goes into a Jayco cleaning machine, which uses a cleaning agent and water to clean the part. Next is final shaping using an electrical discharge machining tool to remove excess metal, followed by heat treating.

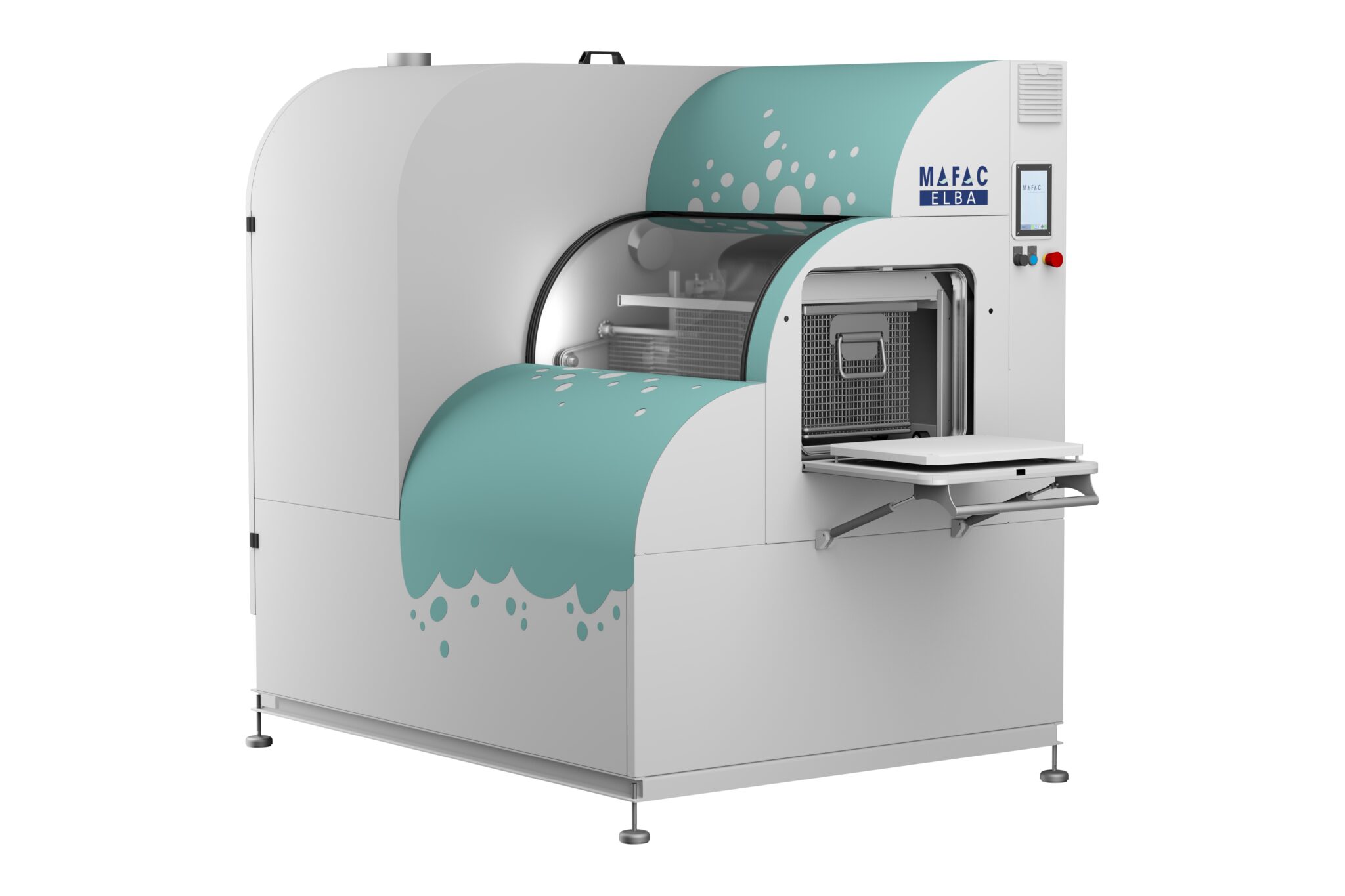

Space-saving design for aqueous cleaning which includes our patented cleaning and drying under vacuum.

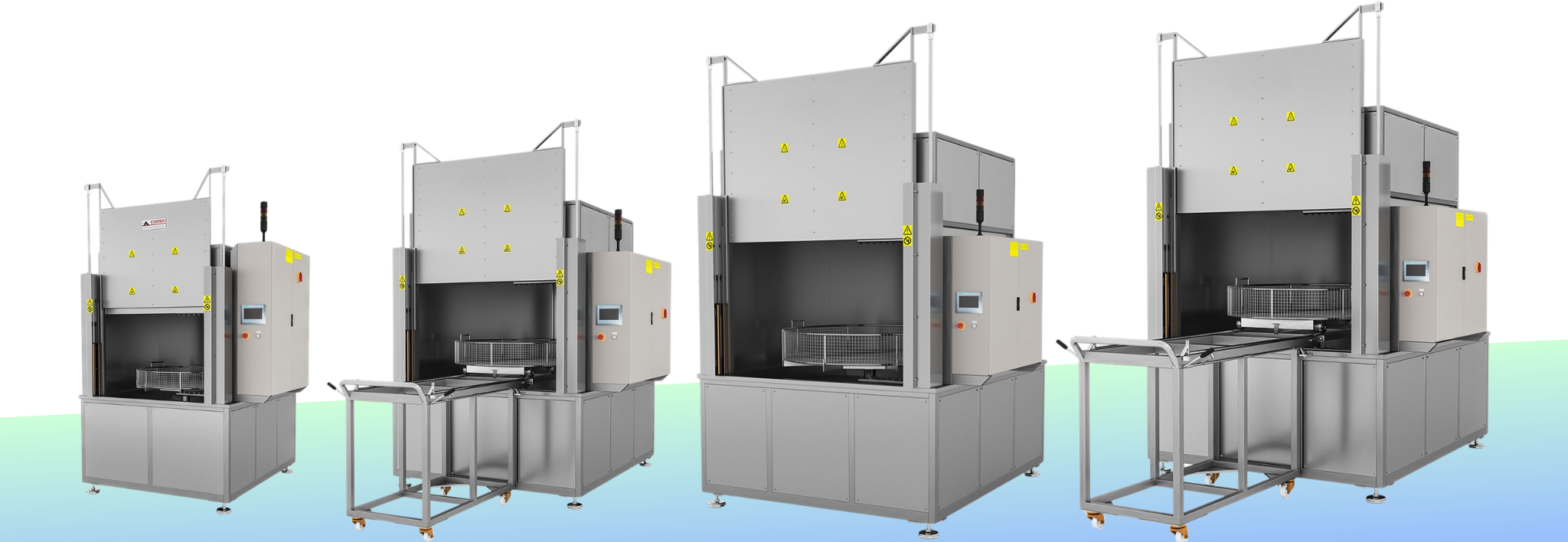

Modular immersion cleaning tanks with ultrasonics, rotation, drying, passivation, and automation.

Large parts capacity cabinet spray washers with separate wash / rinse tanks and hot air dry.

Frequently Asked Questions

Yes, The Boeing BAC 5749 Alkaline Cleaning specification recommends using “water break free” to determine parts cleanliness. While many in the space industry use the IEST 1246, which utilizes a combination of non-volatile residue and particle count to determine cleanliness. Jayco equipment will clean parts to meet both standards.