Medical Device Passivation & Cleaning Processes

Jayco has been delivering certified cleaning and passivation systems for over 15 years to some of the leading OEM and Tier 1 medical device manufacturers in North America.

- Citric or Nitric Passivation

- In-Process Cleaning

- Final Cleaning

- Data Management per FDA 21 CFR Part 11

Medical & Dental Devices

Jayco has experience with providing proven cleaning solutions for the following devices.

- Surgical instruments

- Orthopedic implants

- Vascular implants

- Dental tools and instruments

- Custom additive manufactured

- Guidewire & endoscopic

Manufacturing Soils

We've cleaned practically all traditional and emerging manufacturing process soils used to produce medical devices.

- Rouge and buffing compounds

- Machining oils, EDM fluid, FPI solution

- Particulate

- Additive manufacturing powder

- Polymer debris

Featured Customer

Norman Noble (Medtech Manufacturing)

Norman Noble chose Jayco to invest in a fully automated & validated final cleaning processes including passivation.

Our new Elma cleaning line and shareable validation reports help simplify our customers’ submission and compliance with Regulation (EU) 2017/745 of the European Parliament and are designed to meet the requirements of Annex II.

Modular immersion cleaning tanks with multi-frequency ultrasonics, HEPA drying, and automation.

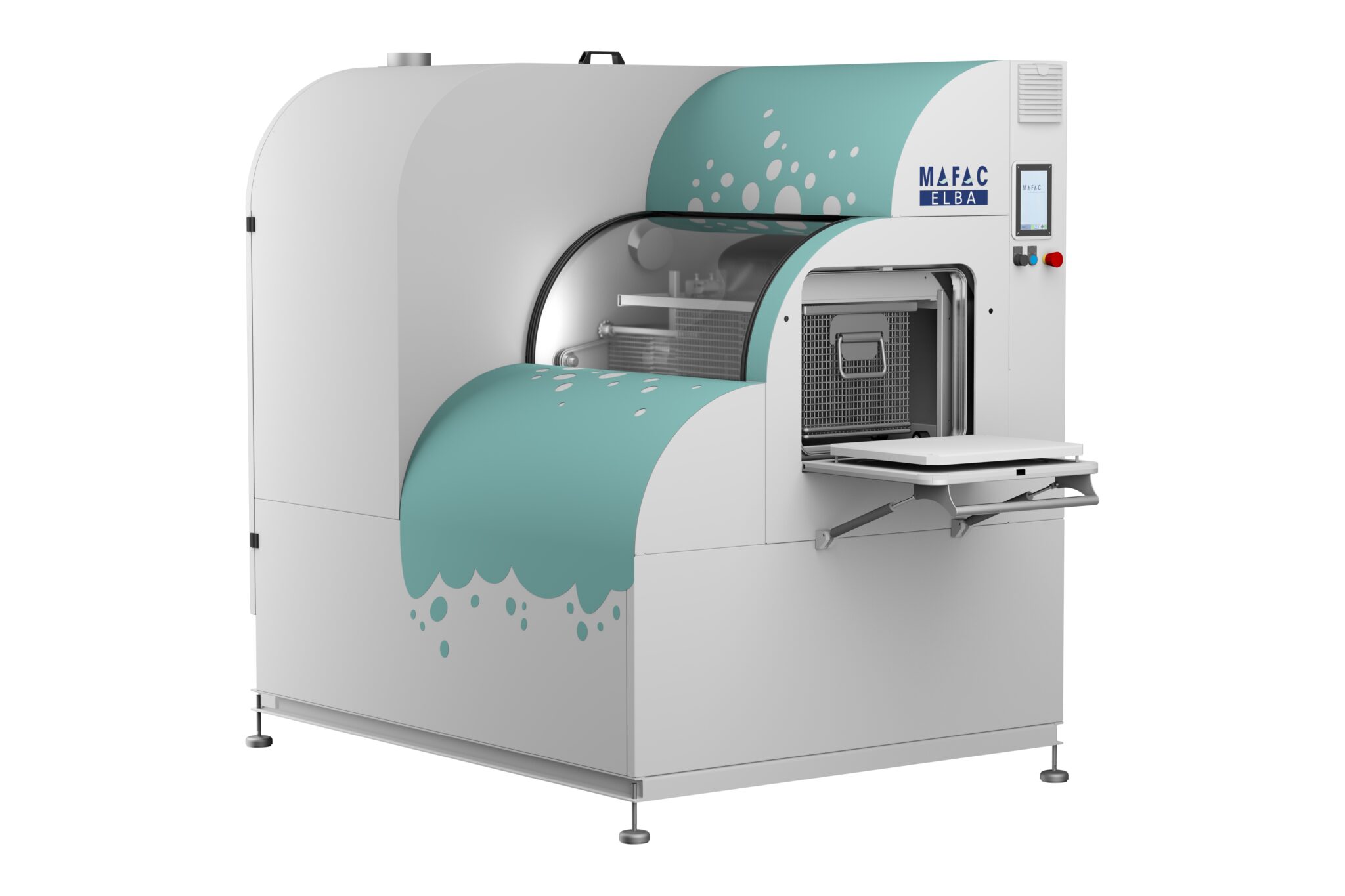

Space-saving design for aqueous cleaning which includes our patented cleaning and drying under vacuum.

Frequently Asked Questions

- In-vitro cytotoxicity test acc. to DIN EN ISO 10993-5

- Bioburden determination acc. to DIN EN ISO 11737-1

- Endotoxins acc. to LAL test USP 85

- Total Organic Carbon - TOC acc. to DIN EN 1484

- Total Hydrocarbon - THC acc. to DIN EN 14039

- Particulate cleanliness acc. to DIN ISO SCP Klassen ISO 14644-9 or VDI guideline 2083 sheet 21

- Passivity of stainless steel surfaces e. g. acc. to ASTM A0967