Industrial Ultrasonic Parts Cleaning of Critical Components

Critical parts require high levels of cleanliness that can be difficult to achieve. Jayco's team of process engineers have a deep understanding of medical, optics, and aerospace industries, taking the guesswork out.

We sit down with you to understand everything from cleanliness specifications, throughput needs, pre and post cleaning operations, available floor space, and regulatory. Nothing is overlooked.

Engineering the right process, ultrasonic cleaning equipment, and chemistry to fit your demanding requirements.

Why Jayco Industrial Ultrasonic Cleaning Systems

Are Known as One of

The Best

-

Ultrasonics

Selectable frequencies for coarse, intermediate and fine cleaning. Multi-function modes plus industry leading power.

-

Parts Drying

Vacuum, hot air, & infrared options deliver moisture free parts regardless of complexity.

-

Inline Passivation

Nitric acid, citric acid, or both processes can be integrated removing the need for secondary operations.

-

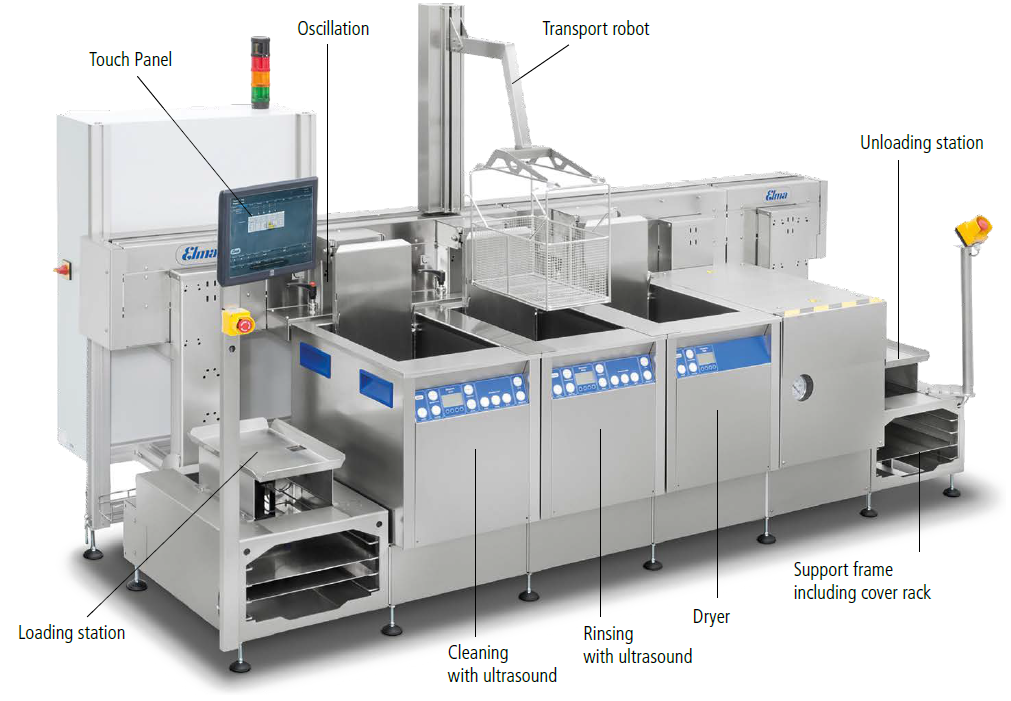

Automation

Conveyer or robot handling. Part rotation and oscillation for the ultimate clean. Automatic chemical dosing.

-

Quality Assurance

Data logging & FDA 21 CFR Part 11. Proven verification for most processes.

-

Reliability

Average 98.9% uptime. Responsive service and USA stocked parts to keep you running.

Featured Customer

Norman Noble (Medtech Manufacturing)

Norman Noble chose Jayco to invest in a fully automated & validated final cleaning processes including passivation.

Our new Elma cleaning line and shareable validation reports help simplify our customers’ submission and compliance with Regulation (EU) 2017/745 of the European Parliament and are designed to meet the requirements of Annex II.

Industrial Ultrasonic Cleaner

Frequently Asked Questions

A 2 years parts / 1 year labor is typical on most systems.