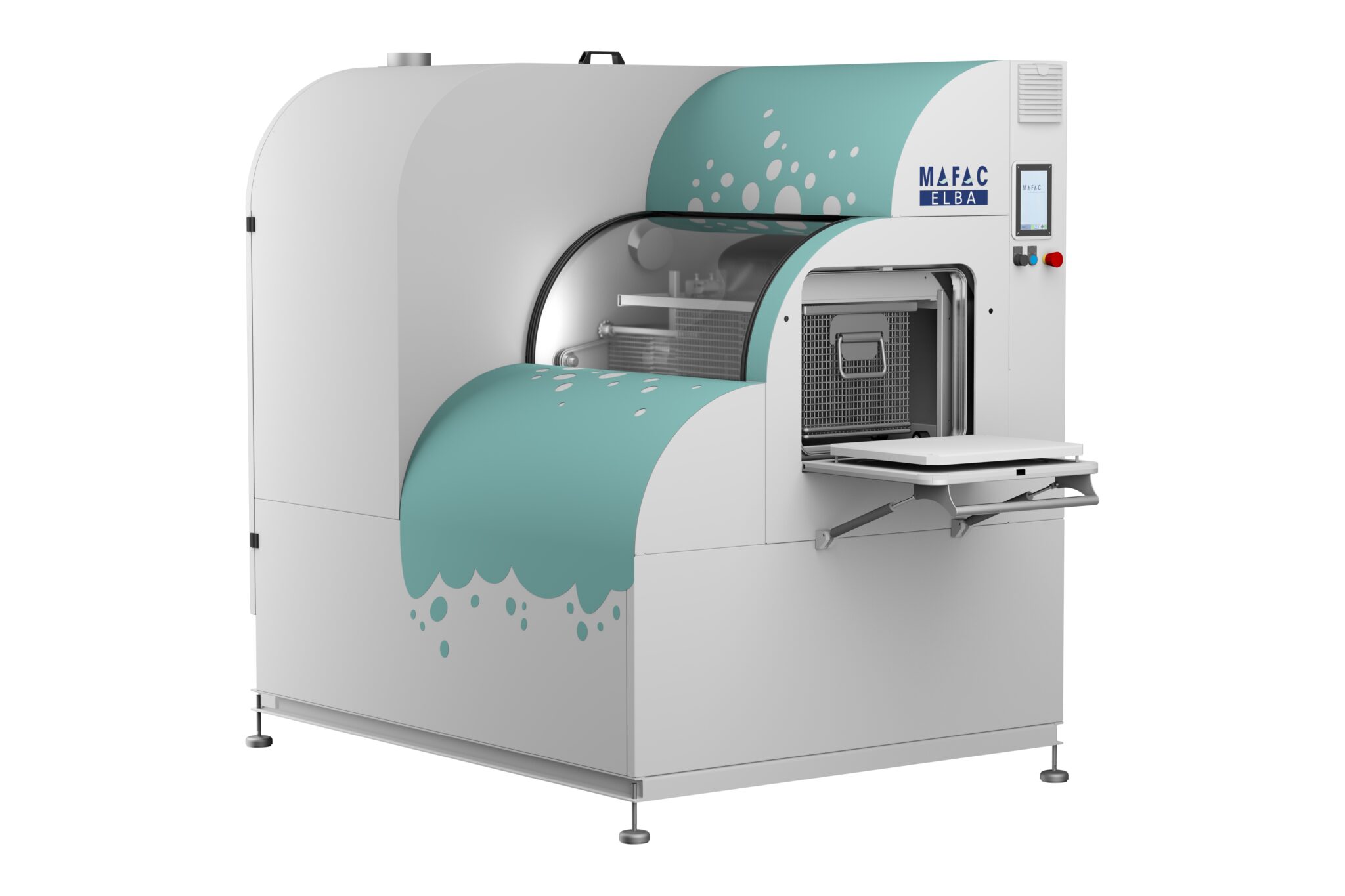

MAFAC ELBA Rotary Basket Parts Cleaning System

-

Parts Cleaning in a Small Footprint

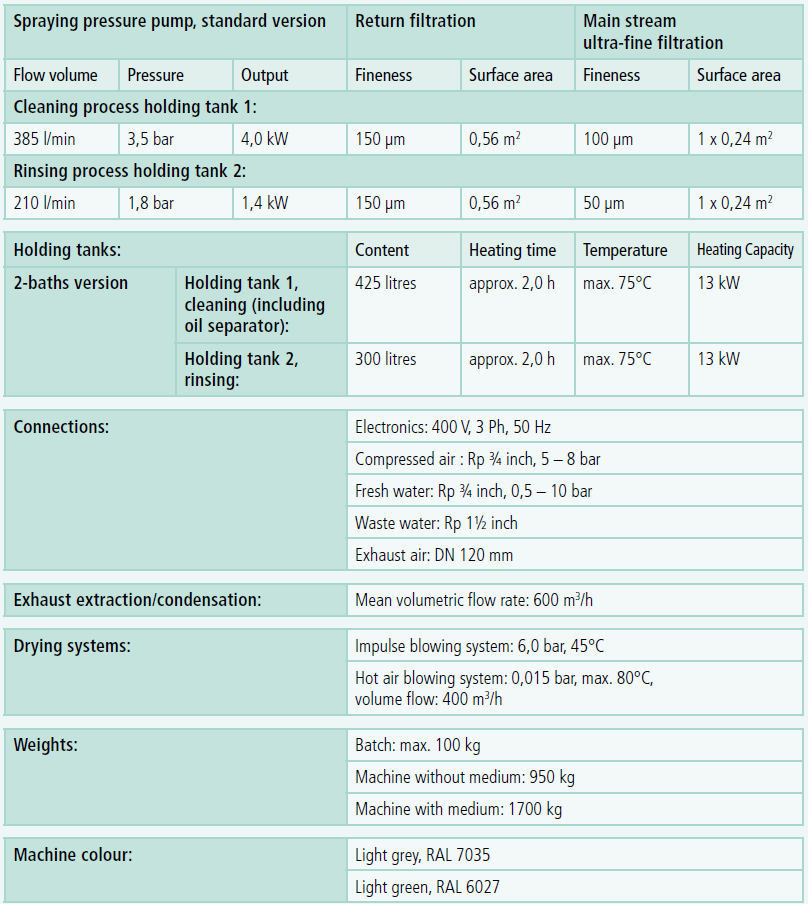

Two tanks for clean and rinse

-

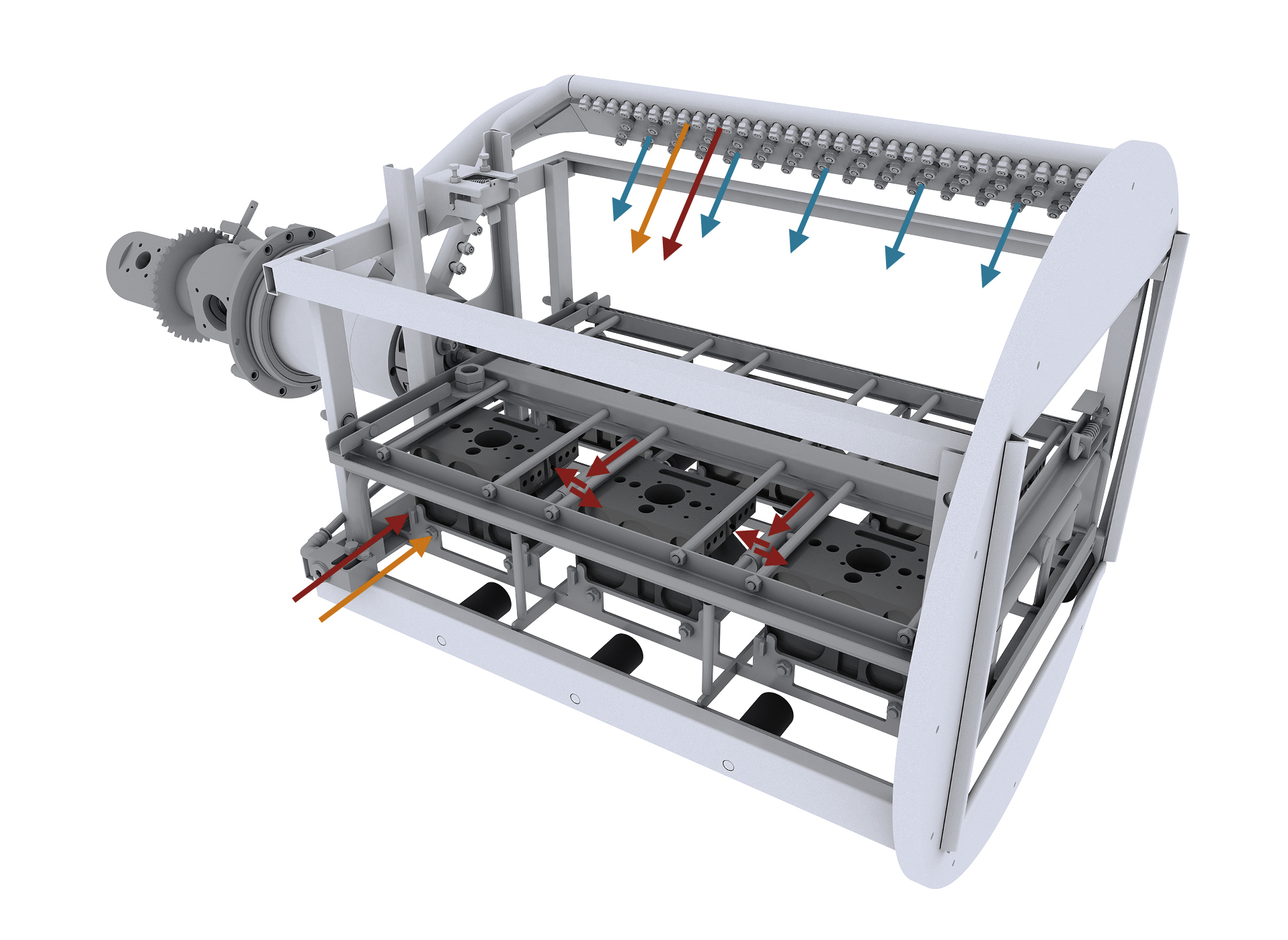

Targeted Spray Cleaning

Patented rotating, multi-sided spray with counter-rotating basket

-

High Pressure Spray up to 50 PSI

-

Rotating Hot Air Drying

Patented technology saves energy with 21% faster drying

-

Powerful Coalescing Oil Separator

Aerospace/Space

- IEST 1246 Product Cleanliness Levels - applications, requirements, and determination

- CGA G-4.1 and ASTM G93 - Cleaning of equipment for oxygen service

Automotive

- ISO 16232 Road Vehicles - cleanliness of components and systems

Videos

ELBA Overview

Targeted Cleaning and Drying