M & M Precision Parts Cleaning Case Study

Insights

M&M Precision Machining won a new 250k part per week contract by significantly upgrading their manual parts cleaning capabilities. The challenge was the part required a 0.020” hole to be free of oil and debris. Jayco’s MAFAC rotary basket washer with Vacuum Assist Clean + Dry™ technology was the only one that could meet the challenge.

Introduction

M&M Precision Machining, located in Elk River MN, is a second generation contract precision machine shop. Brothers Mike and Matt James took over the business from their father at the ages of 19 and 21 in 1992. Their 50 loyal highly skilled employees provide precision machining, turning, grinding and other services to a wide variety of customers.

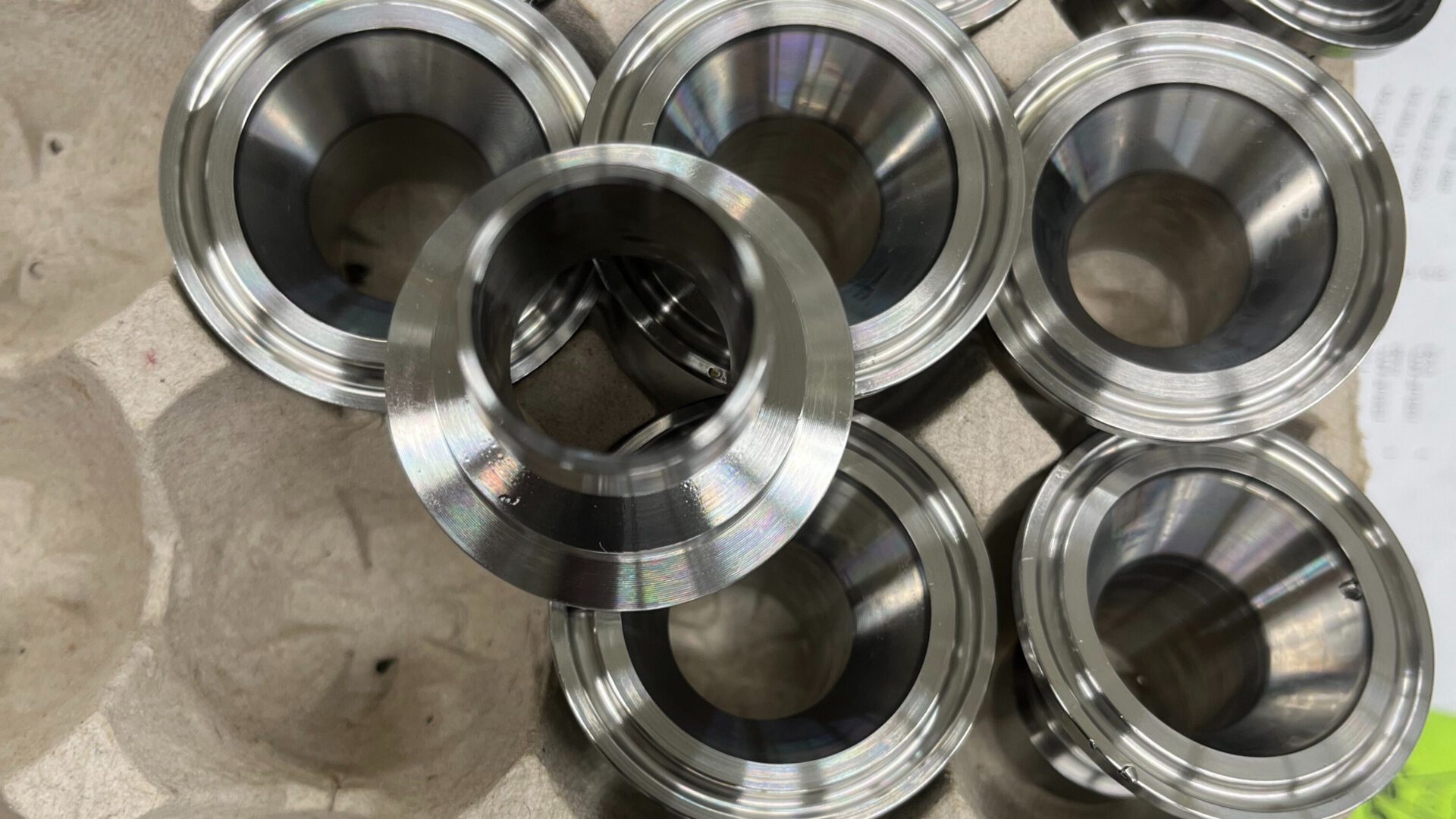

They provide both long and short runs for industries such as precision metal, aerospace, and automotive. The team utilizes over 40 CNC’s including swiss, grinding/honing, milling and EDM systems. As a contract machining facility M&M manufactures a wide variety of parts to customer specifications made of plastics, 6000 series aluminum, brass, steel and 300 series stainless.

Part quality capabilities include a temperature controlled inspection room utilizing microscopes and CMM’s to ensure customer standards and specifications are met. M&M understands that the customer is #1 and doing the job right the first time is key to garnering repeat business.

Problem

Prior to implementing the MAFAC JAVA, M&M did not utilize an automated cleaning system. They used a manual aqueous cleaning process followed by manual drying with shop air to blow the water off of parts.

The parts cleaning process currently removes cutting oils, water soluble coolant and other manufacturing debris. After the cleaning process parts may go back for more machining operations (multiple times in some cases), to an assembly department or to shipping.

The cleaning requirements changed significantly however, with one new prospective customer. A new contract required M&M to provide 250,000 parts per week. The big challenge was the part had a 0.020” hole that was required to be free of oil and debris. A nearly impossible task for any manual process to achieve consistently and with a cycle time that could meet the large volume demanded.

Solution

When a new parts cleaning process was under consideration, M&M reviewed the capabilities of the MAFAC JAVA and several other rotary basket washers. They visited manufacturers and test cleaned parts in each system.

We talked to nearly every competitor that makes similar cleaning systems and ran samples at each. The MAFAC JAVA was the only machine that could meet the production requirement and provide a clean, dry part.

Matt James, Owner

They were looking for a system that could provide a cleaning process that is repeatable and controlled along with providing completely dry parts on intricate features like the challenging 0.020″ hole. Upon evaluating the various systems M&M selected the MAFAC JAVA for their cleaning process.

Results

The JAVA rotary basket washer, which has been in service for many years now, has allowed M&M to greatly improve part cleanliness and drying for all customers that require a clean and dry part.

Parts are cleaned utilizing the spray, spray/flood and ultrasonics which are part of the JAVA wash process. They are then spray rinsed with DI water utilizing the MAFAC patented counter rotation spray wand system.

The enhanced drying is a result of the integrated vacuum drying system used in the JAVA. Vacuum Assist™ can completely remove all water from the most intricate parts machined by M&M.

Today a technician loads parts into a basket, slides the basket into the washer and presses the start button. While the parts are being cleaned the technician now has time to conduct other tasks. Once the cleaning cycle is completed the basket of clean, dry parts are removed from the system and moved on to the next step in the manufacturing process.

Conclusion

The implementation of the MAFAC JAVA into the M&M cleaning process initially allowed the growing company to gain a new, large contract. And since that time has significantly improved the overall part cleanliness and improved efficiency of the parts cleaning process. The Vacuum Assist Clean+ Dry™ system has greatly reduced parts handling and improved the time required to move parts to the next process.