Jayco has been delivering certified cleaning and passivation systems for over 10 years to some of the leading OEM and Tier 1 medical implant and device manufacturers in North America. Surgical instruments, orthopedic and vascular implants, custom additive manufactured, guidewire and endoscopes, we've done it all. Advanced software compliant with 21CFR Part 11 regulations.

We have a deep understanding of precision optical component cleaning from our years of designing systems for many of the leaders in optics. Whether it's final cleaning, IR drying, or fine particulate removal, we have you covered. No guesswork, just results.

Jayco provides advanced solutions to critical aerospace cleaning challenges. Complex turbine blades, critical engine components, fuel nozzles, hydraulic manifolds and components, fasteners, additive

manufactured parts, we’ve done it all. No guesswork, just results.

Jayco has experience with providing proven cleaning solutions that meet the critical cleanliness you require. Additive manufactured, swiss machined, hydraulic components, small ID tubing, PVD, vacuum brazing, we've done it all.

Modular immersion cleaning tanks with ultrasonics, rotation, drying, passivation, and automation.

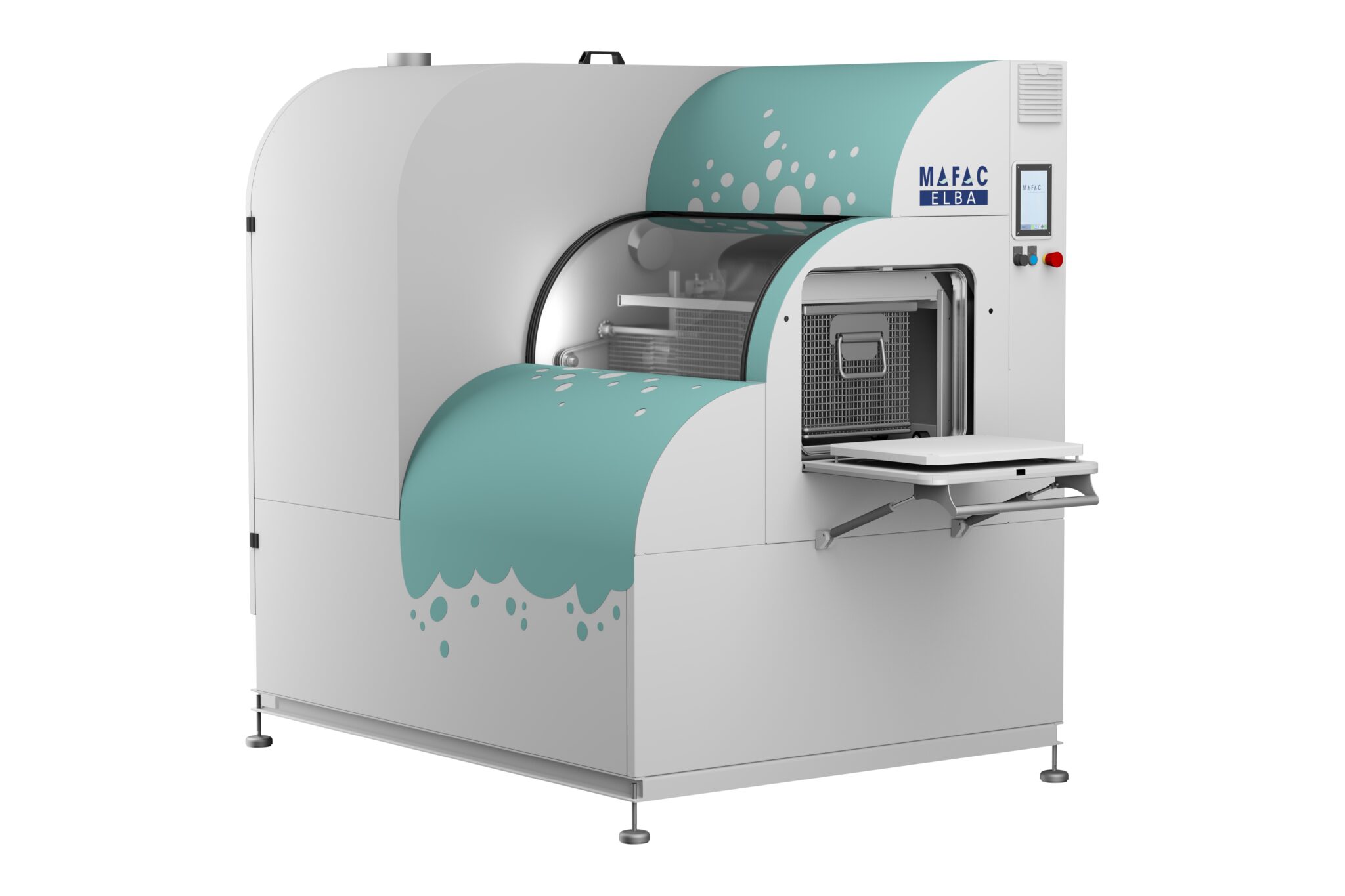

Space-saving design for aqueous cleaning which includes our patented cleaning and drying under vacuum.