Critical Cleanliness Specifications

Critical parts require high levels of cleanliness that can be difficult to achieve. Jayco's team of process specialists have a deep understanding of medical, optics, and aerospace industries, taking the guesswork out and just delivering results.

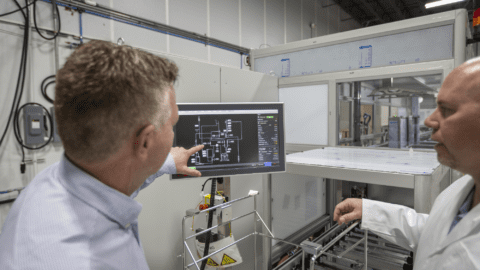

Regulatory & Process Validation

Industries like medical and aerospace are highly regulated which requires process validation along with constant monitoring and record keeping. We understand how to meet medical 21 CFR Part 11 compliance and the OEM aerospace certifications.

Limited Floor Space

Manufacturing floor space can be at a premium many times. Whether you are replacing a system, installing a new one, or looking to convert to cell approach, we can size the system to meet your needs.

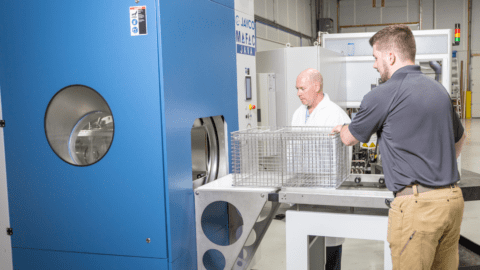

Automation for 24/7 Operation

Skilled labor shortages, lights out operations, or just taking human error out of the equation. Whatever your reason, Jayco has installed dozens of fully automated systems using conveyors and robotics which we can customize for your operation.

Why Customers Choose JAYCO

Expert Process Design

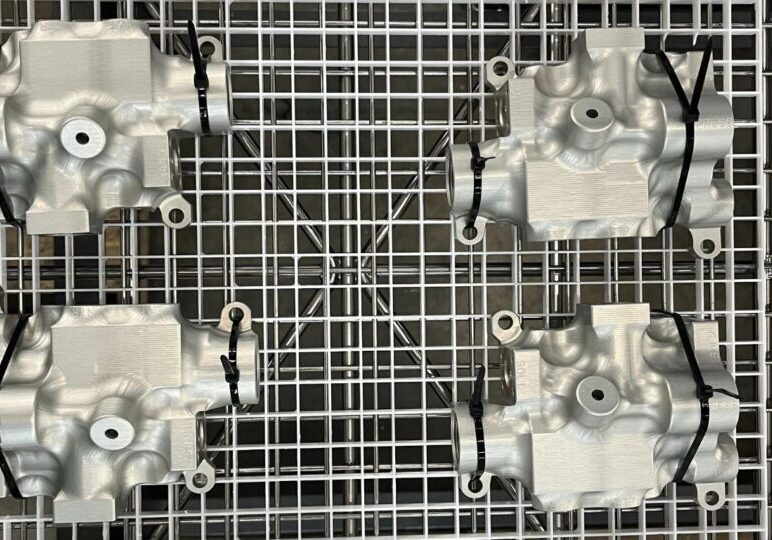

Jayco's team has a deep understanding of critical parts cleaning for medical, optics, aerospace, and precision machined parts.

Learn More -> Why Jayco

Next-Gen Industrial Washers

Jayco ultrasonic and rotary basket equipment consistently delivers results for the toughest cleanliness specifications.

Learn More -> Ultrasonic | Rotary Basket

Responsive Service

Jayco's technical service team is located across the USA, and we can ship parts overnight coast to coast to get you up and running fast.

Trusted by Global Leaders

Vacuum Assisted Cleaning Process Cleaning under vacuum for ultra fine part features.

Learn from Our Latest Posts

Frequently Asked Questions

A 2 years parts / 1 year labor is typical on most systems.