Rotary Basket Washers for Cleaning Critical Parts

Critical parts require high levels of cleanliness that can be difficult to achieve. Jayco's team of process engineers have a deep understanding of medical, optics, and aerospace industries, taking the guesswork out.

We sit down with you to understand everything from cleanliness specifications, throughput needs, pre and post wash operations, available floor space, and regulatory. Nothing is overlooked.

Engineering the right production process, rotary basket parts washer with fixtures, and chemistry to fit your demanding requirement.

Why Jayco Rotary Basket Parts Washers

Are Known as One of

The Best

-

Immersion Ultrasonics

Parabolic reflector for optimal ultrasonic cleaning.

-

Rotating 360° Spray

Patented rotation & multi-sided spray wash with counter-rotating basket.

-

Vacuum Assisted Cleaning Process

Cleaning under vacuum wash for ultra fine part features.

-

Small System Footprint

Compact size yet powerful machine. Up to 3 tanks for clean and rinse.

-

Parts Drying

Rotating impulse blowing, hot air, and vacuum options for optimal drying of complex part features.

-

Industrial Automation

Custom basket conveyer for one or multiple parts washers. Automatic chemical dosing.

-

Reliable Design

Average 98.9% uptime. Responsive service and USA stocked parts to keep you running.

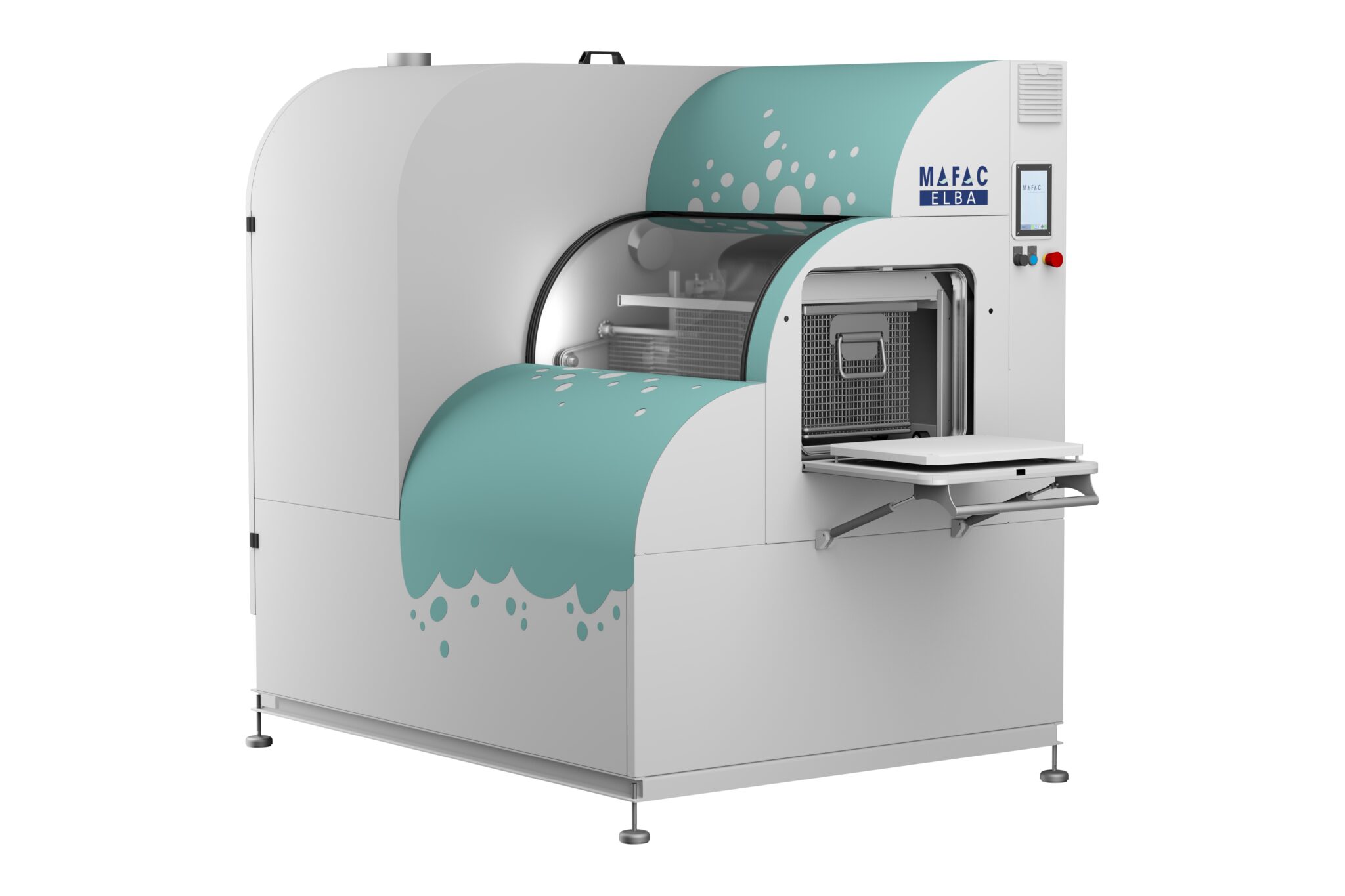

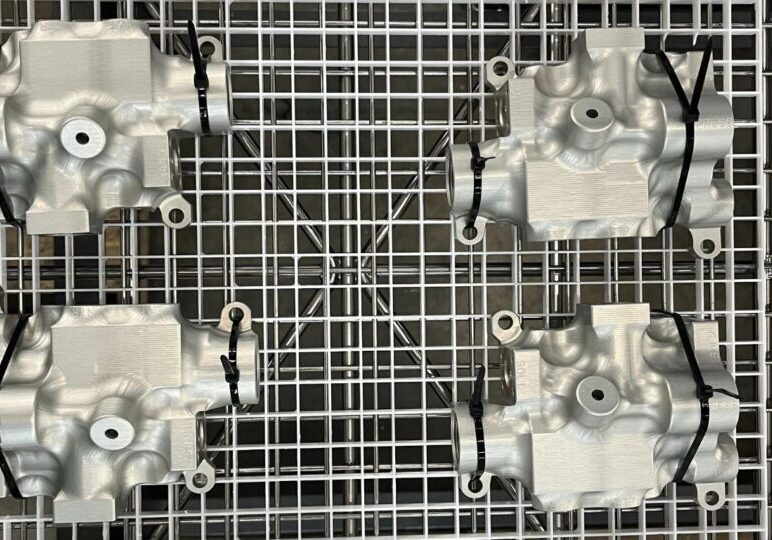

Featured Customer

Micron Manufacturing (Precision Parts)

Micron chose Jayco to invest in a space-saving MAFAC Java rotary basket parts washer with conveyer.

We've run various test parts through the new system. These early results are fantastic, and indicate the system will deliver both a higher cleanliness standard and great time savings. Visually, the cleaned parts come out bright and shining, dry and free of chips.

Learn from Our Latest Posts

Frequently Asked Questions

A 2 years parts / 1 year labor is typical on most systems. Contact us for more details.