Clean & Dry Hard to Reach Areas

Easily with Vacuum Assist

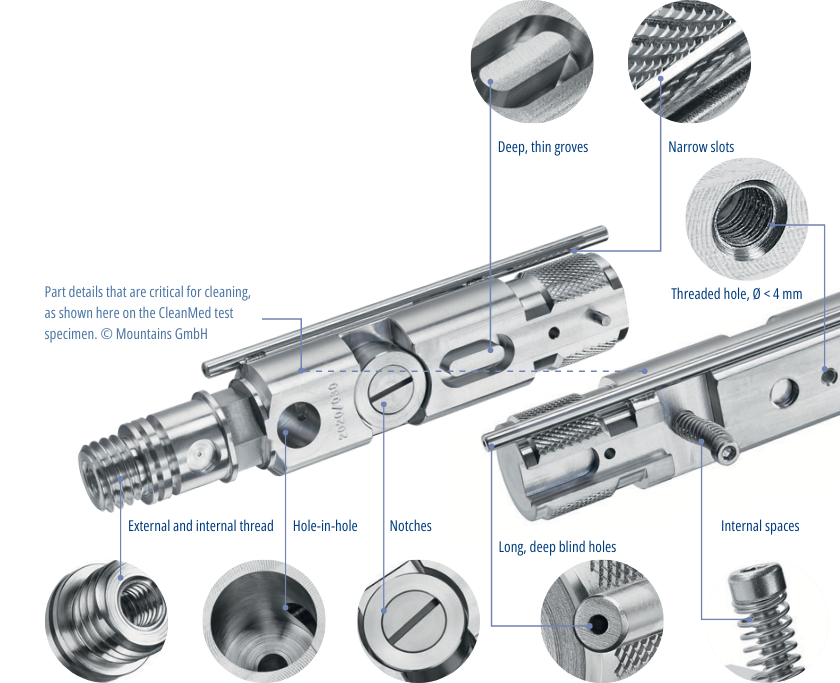

If you are manufacturing complex parts with fine features, you've likely struggled with getting your parts thoroughly clean and dry. Vacuum assisted clean & dry technology makes the job easy.

- Small or blind holes

- Complex fine features

- 3D printed parts

- Failing part cleanliness specifications

- Multiple washes leading to long cycle times

Vacuum Assisted Clean + Dry

Technology for

Hard to Clean Parts

-

Thoroughly Clean

Vacuum assist allows the wash and rinse baths to reach every crevice.

-

Dry Spot Free Features

Drying is sped up while the vacuum pulls water off the surface.

-

Lower Drying Temperatures

Temperature sensitive material can be dried without damage.

-

Cool to the Touch

No need to wait for the part to cool before handling or the next process.

-

Meet Spec w/o Over-Cleaning

Faster cycle times as you don't need to run longer and multiple cycles to hit spec.

How Vacuum Assist Works

Wash Cycles

Modulating vacuum during the wash cycle allows cleaning solution to reach fine areas lifting soils and particulates out thru mechanics and chemistry.

Rinse Cycles

Modulating vacuum during the rinse cycle allows rinsing solution to reach fine areas completely flushing out any remaining cleaning solution and particulates.

Drying Cycle

A vacuum is drawn, lowering the evaporation temperature of the remaining rinse solution. The force from the vacuum also pulls water out of hard to reach areas.

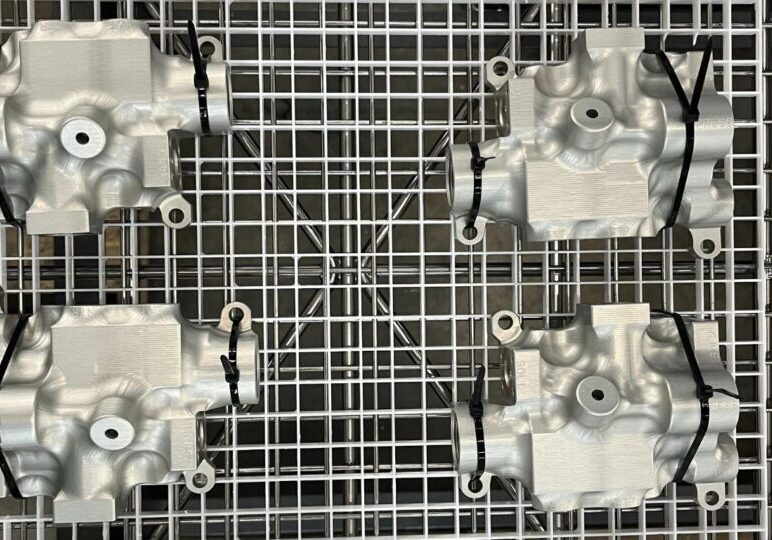

Featured Customer

Micron Manufacturing (Precision Parts)

Micron chose Jayco to invest in a space-saving MAFAC Java rotary basket parts washer with conveyer.

We've run various test parts through the new system. These early results are fantastic, and indicate the system will deliver both a higher cleanliness standard and great time savings. Visually, the cleaned parts come out bright and shining, dry and free of chips.